Driving Innovation: Mesh Morphing Solutions for the Electronics and Electric Industries

Explore the future of electronics and e-motors components design with the integration of mesh morphing technology. At our core, we don’t just provide software; we offer tailored solutions. We understand the complexities of specific industrial challenges and aim to solve them through the seamless integration of mesh morphing technology. Whether it’s optimising electronic circuitry or revolutionising electric motor efficiency, our solutions are crafted to meet the unique needs of our clients. In the field of electronics and electrification, as in other sectors, morphing can be either a simple change in shape or a shape transformation aiding simulations.

The reliability aspect of mechanical simulations for electronic components is crucial, and RBF Morph is rapidly expanding in this sector, already serving top-tier and mid-sized clients

In the realm of electronic circuits, mesh morphing introduces a dynamic dimension to design. Imagine circuits that adapt and optimise their structure in response to varying conditions. Electronic engineers designing circuits traditionally use ECAD tools to carry out the entire electronic design process. From these systems, they can generate planar printed circuit boards (PCBs), even if they are highly complex. Transforming flexible PCBs into curved shapes can be challenging. Consider a set of circuits that, once assembled, need to be bent, for example, to fit the walls of a container.

With mesh morphing, we can take the initial flat model, which is not suitable for calculations, and transform it into the shape it will have after assembly. This allows engineers to perform all the necessary calculations in a virtual environment. Incorporating mesh morphing technology in the design process provides multiple benefits, such as cost reduction and improved performance and durability of PCBs.

Choose our mesh morphing technology for a future where manufacturing errors become a thing of the past

In scenarios where a flat board must be securely mounted inside a metal component, our innovative approach can ensure optimal performance and durability. Imagine a situation where a flat board, intended for mounting within a metal component, may encounter challenges during assembly. If the board deviates from complete flatness, acquiring a slight curvature during manufacturing or assembly, traditional methods risk breakage during the screwing process. Conventional screws can force the board back to a flat position, resulting in potential damage.

Engineers meticulously record how the flat board distorts under various conditions. Leveraging this valuable data, we use morphing technology to adjust the complex Finite Element Model (FEM). This advanced FEM now precisely mirrors the acquired experimental shape. This process enables the model to calculate the optimal tightening of screws during assembly. By predicting and accommodating the board’s inherent curvature, our mesh morphing tools ensures a seamless fit, reducing the risk of breakage. This not only enhances the overall reliability of your components but also significantly minimises development costs.

Discover our cutting-edge solutions for electronic component testing and simulation

In the world of electronics, where components often need to endure bending during assembly, our innovative approach ensures robustness and reliability. Traditionally, subjecting electronic components to a bending test involves 100 bends using specialised equipment, aiming to assess their resilience without compromising internal copper traces that carry vital signals. The challenge lies in efficiently simulating these tests using conventional software, which can take weeks of intricate calculations.

Our revolutionary morphing solutions can accelerate and enhance the simulation process. Our approach significantly reduces simulation time, allowing the Finite Element Model (FEM) to calculate stress levels in a matter of hours. This efficiency not only saves valuable time but also produces highly accurate and reliable results.

Choose innovation, choose efficiency, choose our morphing technology for a future where electronic component testing is streamlined and results are delivered with unprecedented speed and precision. We are revolutionising the landscape of electronic component testing.

When it comes to electric motors, mesh morphing opens doors to unprecedented efficiency.

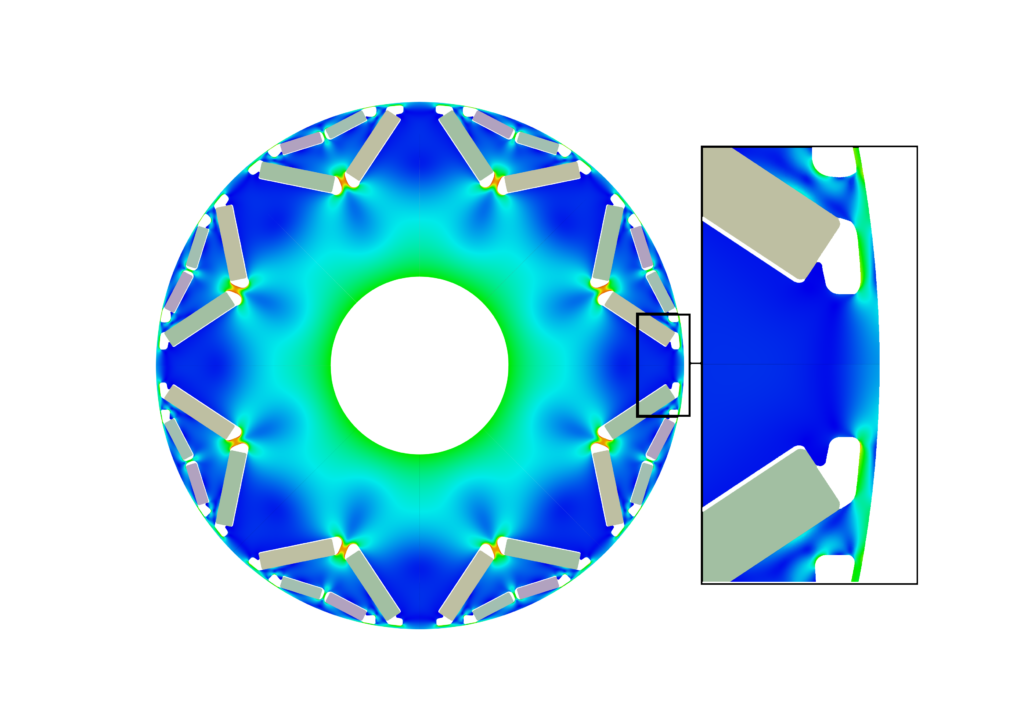

In addition to electronics, we are also working in the electrification field. Currently, we are conducting basic structural analysis of electric motors. When the motor rotates at high speed, there is a centrifugal force acting on the structure in relation to the connected magnets, which are heavy. We can simulate and morph this force to optimise designs. We perform optimization by considering both electromagnetic and structural analyses.

Step into a future where the electronics and electric industries leverage mesh morphing for advanced simulations. Elevate your engineering endeavours with our advanced solutions designed to tackle the challenges of today and tomorrow.

Reach out to discover the ideal RBF Morph solution for your industrial requirements.