We are pleased to announce the publication of an important work in MDPI titled “Prosthetist-Specific Rectification Templates Based on Artificial Intelligence for the Digital Fabrication of Custom Transtibial Sockets.” The study, authored by Andrea Giovanni Cutti, Maria Grazia Santi, Andrew H. Hansen, Stefania Fatone, and the Residual Limb Shape Capture Group, represents a significant advancement in the field of prosthetics.

RBF Morph is proud to have developed and provided the Python version of the software used in this groundbreaking research.

Overview of the Research: The focus of the study is on the fabrication of transtibial prosthetic sockets, specifically addressing the time-consuming and often inconsistent process of manually rectifying a plaster model of the residual limb. This variability arises from the reliance on implicit knowledge among different prosthetists.

The research outlines a novel approach that utilizes artificial intelligence (AI) to generate prosthetist-specific digital rectification templates. These templates are applied to the shape of the residual limb in a way that reflects the unique rectification style of individual prosthetists.

Key Components:

- Data Acquisition: A dataset of unrectified and rectified positive models was created through manual data collection and 3D scanning.

- AI Application: An AI algorithm learned the rectification rules used by the prosthetist, allowing the automatic application of these rules to new residual limb models.

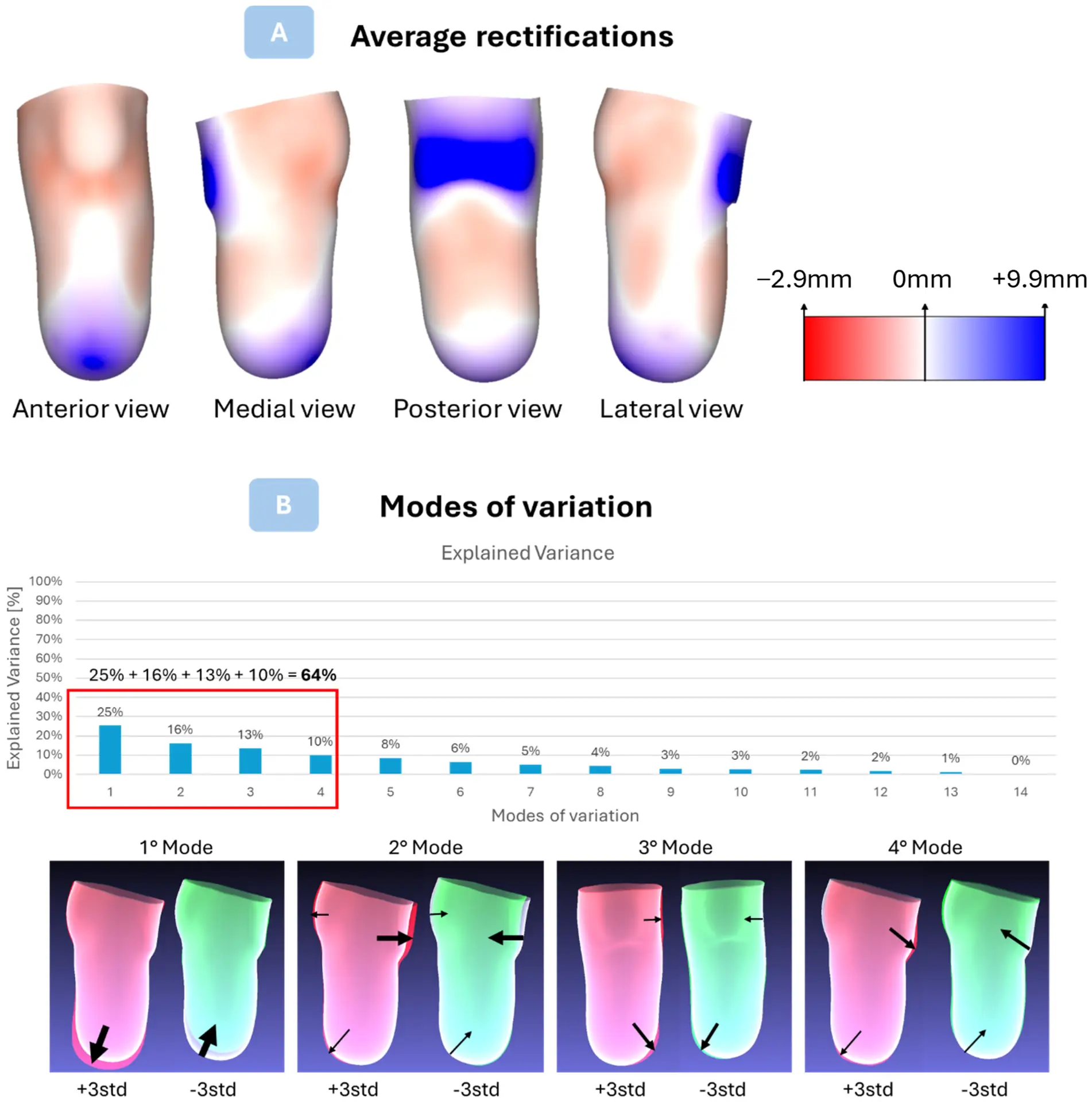

Results: The study found that the AI-generated rectifications were consistent with the prosthetist’s manual approach, showing minimal radial and angular deviations. The overall dimensions, including volume and cross-sectional perimeters, were comparable to manually rectified models.

Implications: This research provides a proof-of-concept for integrating AI into the prosthetic socket fabrication process. Once refined, this approach has the potential to streamline the workflow for prosthetists, providing a faster and more consistent starting point for creating custom prosthetic sockets.

We are proud to contribute to this innovative application of AI in healthcare, supporting advancements that will improve patient outcomes and prosthetist efficiency.

Click to download the paper.