A very interesting article having title Automatic shape optimisation of structural parts driven by BGM and RBF mesh morphing has been published on the International Journal of Mechanical Sciences Volume 183 – available online 25 July 2020 –

Authors: S. Porziani; C. Groth; W. Waldman; M.E. Biancolini.

Abstract

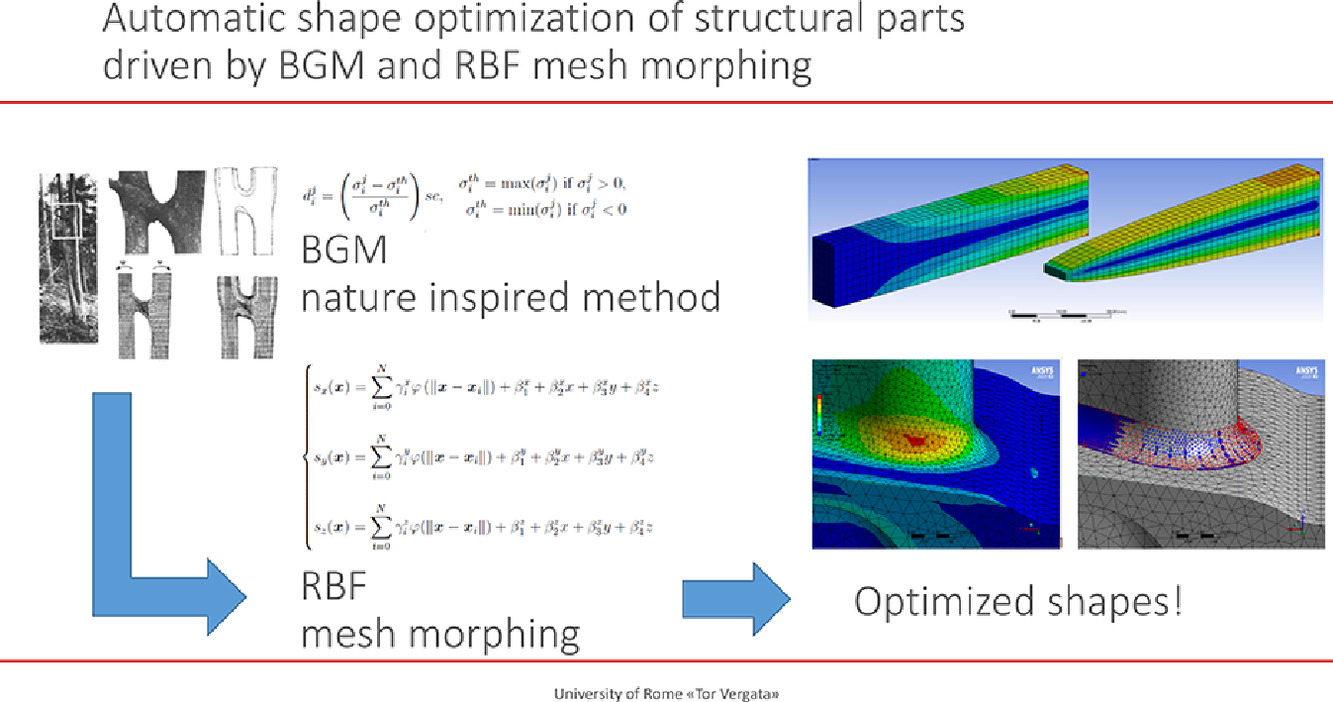

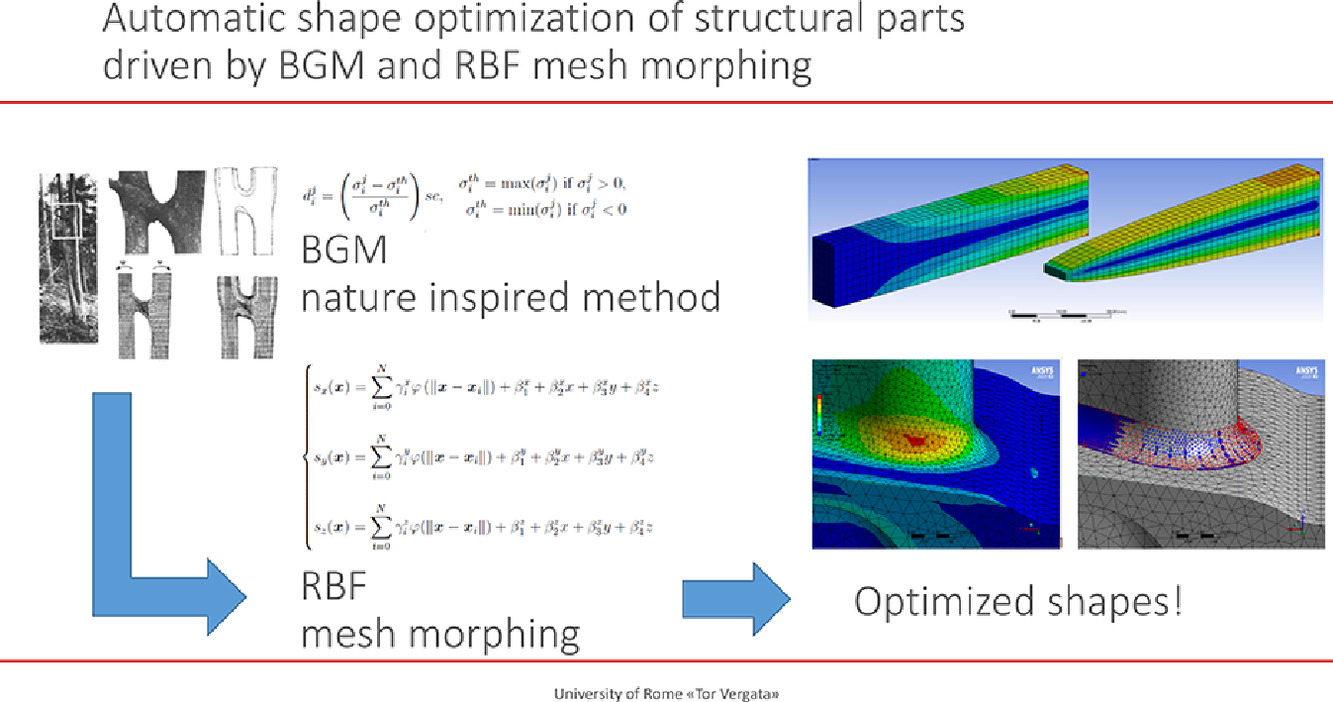

The great flexibility of emerging production processes based on additive manufacturing is stimulating the development of automatic shape optimisation methods. Complex optimised shapes that were previously discarded because of prohibitive construction costs are now affordable. These new designs are obtained through the application of the biological growth method (BGM), which mimics the mechanism of growth that occurs with animal bones and tree trunks. Biological structural parts self-adapt their shape by promoting surface growth at more stressed locations. This behaviour can be adapted to the design optimisation of structural parts, which can be thickened or lightened by updating the shape of the finite element model used for stress analysis.

The method used to modify the finite element mesh is a critical consideration, and this paper presents a mesh morphing approach based on radial basis functions (RBFs) that is suitable for complex industrial applications. The computational mesh of the solid part is controlled by using BGM-driven algorithms to reshape its surfaces, which are sculpted by moving them inward or outward in a direction parallel to the local surface normal of the geometry. The deformation is propagated into the volume by interpolating the mesh field using RBFs. The bi-harmonic global-supported RBFs maintain a high quality mesh even for large deformations.

The proposed approach is demonstrated using an industrial implementation based on the ANSYS Mechanical finite element solver and the mesh morphing extension RBF Morph. The first example studied is a cantilever beam with an initial rectangular cross section, and a 33% reduction in mass is achieved. A second example consists of a complex-shaped turbine blade, for which significant reductions in peak stress are obtained at three hotspots located on the blade fillet.

Click here to purchase it.

Enjoy the read!