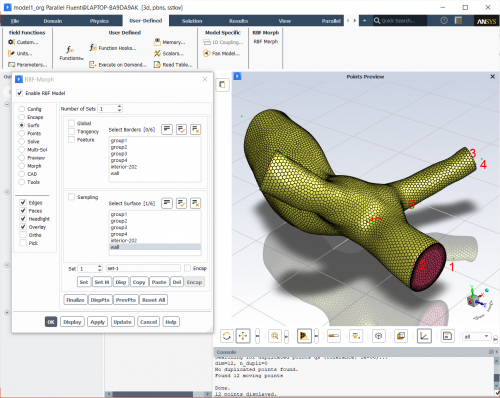

RBF Morph Fluids is an add-on which allows for shape optimization studies entirely within ANSYS Fluent by morphing an existing mesh.

Optimise shapes by morphing existing trusted meshes

This new approach takes advantage of the ANSYS Fluent’s CFD technology and overcomes the limits of the mainstream methods by introducing these functionalities through the implementation of dedicated routines in the CFD ANSYS Fluent code.

A dedicated Graphical User Interface (GUI) has been developed and integrated in ANSYS Fluent. The product helps CFD users without the need to learn another software package. Main features include:

- Product Integration: full integration with ANSYS Fluent.

- User Interface: dedicated GUI and TUI (scriptable).

- Process Integration: morphing directly inside the solving stage without modifying the geometry, regenerating the mesh and setup again the case.

- Mesh Topology: modification of the original surface and volume mesh producing a nodal smoothing without changing the mesh topology.

- Surface Morphing: surface meshes can be modified by free surface deformation, rigid movement or scaling.

- Volume Smoothing: high quality smoothing of the volume mesh with relatively large movements possible in a single step deformation.

- Versatility: nodal smoothing is achieved by means of a meshless approach that is independent from the mesh structure, handling every kind of mesh element type (tetrahedral, hexahedral, polyhedral, prismatic, hexcore, non-conformal interfaces, etc.).

- Reusability: the RBF solution can be applied to any mesh representing the same geometry.

- Consistency: mesh characteristics are preserved so mesh consistency is ensured (element size, type and distribution, prism layers, etc.).

- Parallelism: parallel calculation for large models (many millions of cells).

- Efficiency: flow solutions are fully readable through all the morphed mesh, reducing the number of iterations to converge.

- Precision: exact movement is ensured for the moving nodes locations as well as exact feature preservation.

- Parameterization: multi-parameter and multi-step problems.

- CAD: transfer modifications back to CAD by applying to STEP files similar modifications done on the mesh in order to fully support the re-design of the morphed surfaces.

- Automatic shape sculpting driven by CFD solution results (Adjoint Solver).

- Product Integration: full integration with ANSYS Fluent.

- User Interface: dedicated GUI and TUI (scriptable).

- Process Integration: morphing directly inside the solving stage without modifying the geometry, regenerating the mesh and setup again the case.

- Mesh Topology: modification of the original surface and volume mesh producing a nodal smoothing without changing the mesh topology.

- Surface Morphing: surface meshes can be modified by free surface deformation, rigid movement or scaling.

- Volume Smoothing: high quality smoothing of the volume mesh with relatively large movements possible in a single step deformation.

- Versatility: nodal smoothing is achieved by means of a meshless approach that is independent from the mesh structure, handling every kind of mesh element type (tetrahedral, hexahedral, polyhedral, prismatic, hexcore, non-conformal interfaces, etc.).

- Reusability: the RBF solution can be applied to any mesh representing the same geometry.

- Consistency: mesh characteristics are preserved so mesh consistency is ensured (element size, type and distribution, prism layers, etc.).

- Parallelism: parallel calculation for large models (many millions of cells).

- Efficiency: flow solutions are fully readable through all the morphed mesh, reducing the number of iterations to converge.

- Precision: exact movement is ensured for the moving nodes locations as well as exact feature preservation.

- Parameterization: multi-parameter and multi-step problems.

- CAD: transfer modifications back to CAD by applying to STEP files similar modifications done on the mesh in order to fully support the re-design of the morphed surfaces.

- Automatic shape sculpting driven by CFD solution results (Adjoint Solver).