In his thesis ‘Structural Optimization of an Automotive Wheel Rim’ Luca Cerniglia showed the advantages of using RBF Morph Structures to help optimize the shape of a car wheel rim.

Abstract:

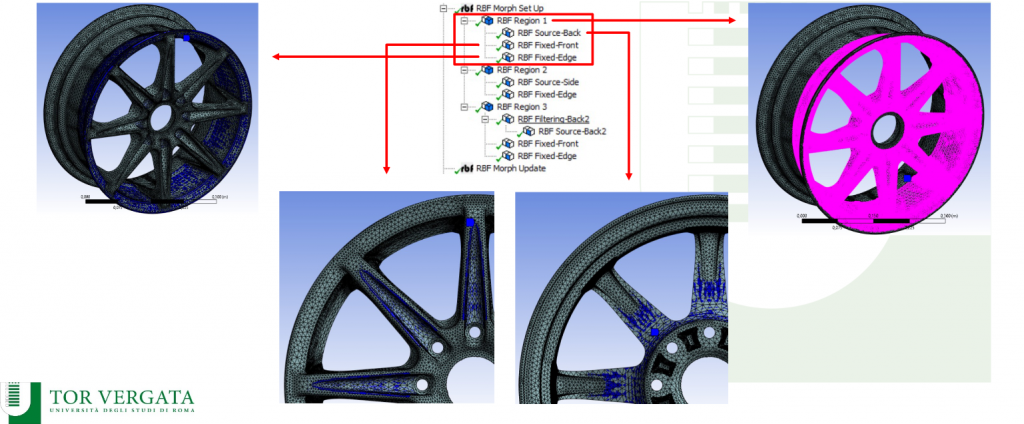

The following work aims to carry out a structural analysis and subsequent shape optimization of an automotive wheel rim. The TÜV Rheinland certification and the related load tests necessary for the approval of non-OEM alloy wheels were used as a reference. In the first part, the stress state that occurred within the body was compared with the allowable stress values using finite element methods. This was followed by a shape optimization process using mesh morphing and the theory of radial basis functions (RBF). All of this was done in the Ansys Workbench environment using software provided by the Ansys package (in particular Ansys Mechanical, OptiSLang and Ansys RBF Morph Structures). A mass reduction of approximately 5.35% was achieved, while ensuring that the final component still passed the required load tests.

To view our section of theses or dissertations, click here.